Ravenwood VXR

Packaging Machinery

Information

This new compact state-of-the-art Ravenwood VXR X-Ray Inspection Machine with Vision Label Inspection will embrace Vision, X-Ray, and Sealing technology, providing an all-inclusive process for the seamless production of sleeving and contaminate detection, using “Sapphire Technology.” All under the operation of just one machine – the ‘end of line’ solution to meeting the food industry’s stringent requirements. Customers can benefit from fully automating their production lines without the need for manual quality checks. Machines can be built bespoke to feature just one of these elements or all three.

Vision:

- Identifies and rejects errors, enabling operator-free end of line automation

- Automatically detects faulty labels: printing errors and poor-quality print

- Analyses label position, quantity, and orientation

- Checks all printed information: bar codes, use-by dates and traceability codes

- High speed checking via user-friendly interface

- Factory proven rugged hardware and Software

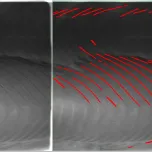

X-Ray:

- Heightened sensitivity for detecting dense mass / contaminants

- Identifies foreign bodies such as glass, metal and ceramics

- Senses bone

- High speed checking via an easy-to-use interface

Options:

- XR – X-Ray Contamination, X-Ray Seal Inspection, Vision Upgradable

- VR – Vision Label, Inspection X-ray, Upgradable

- VXR – Vision Label Inspection, X-Ray Contamination, X-Ray Seal Inspection

- VXR & Nobac 5000 – Vision Label Inspection, X-Ray Contamination, X-Ray Seal Inspection, & Nobac 5000 for applying faultless linerless labels to food trays