Intelligent Crab Processing

Shellfish Processing Machinery

Information

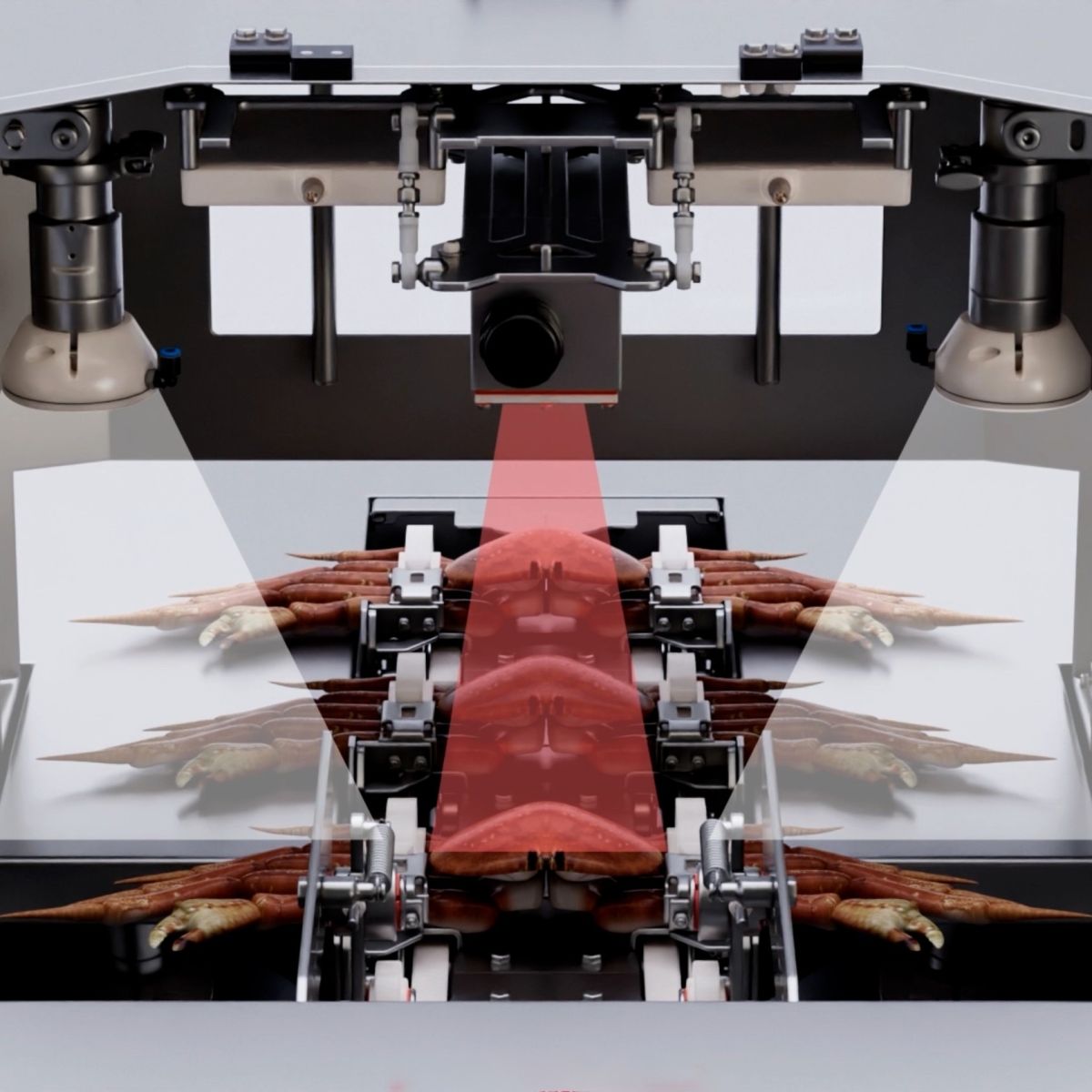

Automated Shine

BAADER 2602 introduces a completely new way of cleaning crab: Instead of cleaning individual clusters, the BAADER 2602 conveys the whole crab maintaining strength of legs and improving resistance to external forces. Whole raw material processing minimizes leg damage and loss.

Safety first: the BAADER 2602 avoids worker injuries by hiding all processing behind state-of-the-art protection covers. BAADER 2602 removes the majority of raw material contaminants like barnacles, leech eggs, moss, and slime.

Depending on legal requirements, BAADER suggests gentle stunning of the raw material prior to the process in order to assure loss of conciousness.

Intelligent Snow Crab Splitting

BAADER 2802 is our answer to the market’s demand for more automation in snow crab processing. Keeping all the benefits of its predecessor 2801, the BAADER 2802 significantly improves safety and accuracy in snow crab splitting with unbeaten Performance.

Depending on legal requirements, BAADER suggests gentle stunning of the raw material prior to the process in order to assure loss of consciousness. The BAADER 2802 provides immediate gutting and splitting results at highest yield.